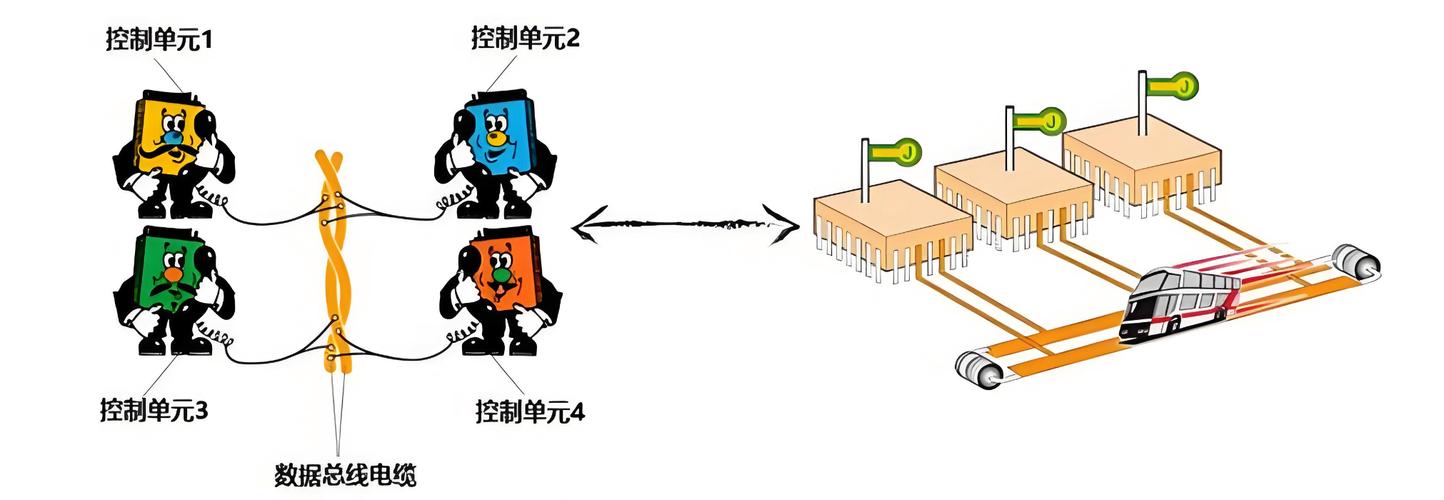

The Controller Area Network (CAN) bus is a robust serial communication protocol widely used in automotive, industrial, and embedded systems for real-time data exchange between electronic control units (ECUs). Its reliability, fault tolerance, and cost-effectiveness have made it a standard in modern vehicle networks, enabling efficient communication among components like engine control modules, airbag systems, and infotainment units. This protocol, originally developed by Bosch in the 1980s, operates on a multi-master serial architecture with differential signaling, ensuring high noise immunity and data integrity even in harsh electromagnetic environments.

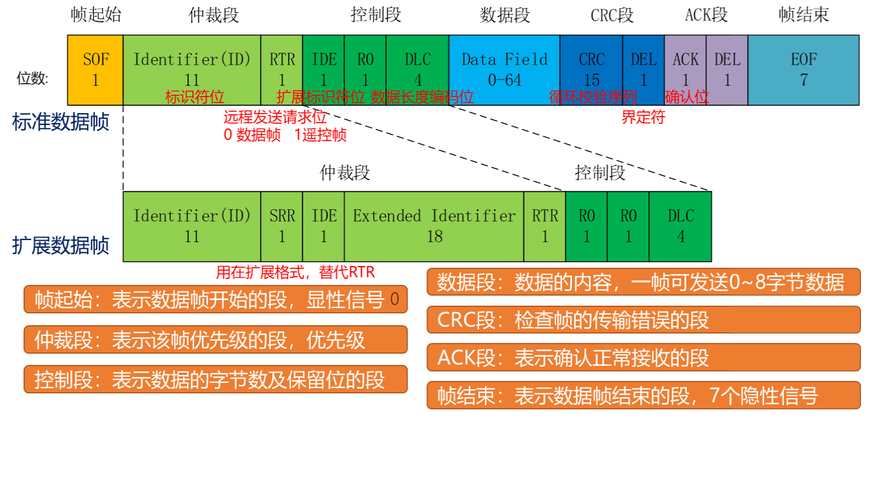

Key characteristics of CAN bus include its non-destructive bitwise arbitration, which resolves message collisions prioritizing higher-priority messages based on their identifier values, and its error detection mechanisms such as cyclic redundancy checks (CRC) and bit monitoring. The physical layer typically uses a twisted-pair cable with termination resistors to minimize signal reflections, while the data link layer defines frame structures, including data frames, remote frames, error frames, and overload frames. CAN bus supports data rates up to 1 Mbps for shorter distances (e.g., 40 meters) and lower rates (e.g., 50 kbps) for longer distances (up to 1000 meters), making it adaptable to various application requirements.

In automotive applications, CAN bus facilitates real-time coordination among ECUs, enabling functions like anti-lock braking systems (ABS), adaptive cruise control, and powertrain management. Its deterministic nature ensures that critical messages are transmitted within predictable time frames, which is essential for safety-critical systems. Beyond automotive, CAN bus is employed in industrial automation for connecting sensors, actuators, and programmable logic controllers (PLCs), as well as in medical devices and aerospace systems where reliable communication is paramount.

The evolution of CAN bus has led to variants like CAN FD (Flexible Data Rate), which increases data payload capacity and transmission speed while maintaining backward compatibility with classical CAN. CAN FD supports data rates up to 8 Mbps and larger data frames (up to 64 bytes compared to 8 bytes in classical CAN), addressing the growing demand for higher bandwidth in modern vehicles with advanced driver-assistance systems (ADAS) and electric powertrains.

When researching CAN bus, English-language references provide comprehensive insights into its technical specifications, implementation challenges, and applications. Below is a table summarizing seminal English references on CAN bus, including books, journal articles, and standards, which offer foundational knowledge and recent advancements:

| Reference Type | Title/Author | Key Contributions |

|---|---|---|

| Book | Automotive LANs and CAN by Wolfgang Ecker (2003) | Covers CAN bus fundamentals, protocols, and automotive applications, including case studies on ECU integration. |

| Book | Controller Area Network: Theory and Practice by Wilfried Voss (2025) | Details CAN bus physical layer, frame structures, arbitration mechanisms, and troubleshooting techniques. |

| Journal Article | "A Survey of CAN Bus Protocols and Applications" by S. A. Khayam et al. (2003) | Reviews CAN bus history, variants (e.g., CANopen, DeviceNet), and industrial/automotive use cases. |

| Standard | ISO 11898-1:2025 (Road vehicles—Controller Area Network) | Defines CAN bus physical signaling and media access control (MAC) specifications for interoperability. |

| Journal Article | "CAN FD: The Next Generation of CAN" by M. Löhning et al. (2007) | Explores CAN FD enhancements, including higher data rates and larger payloads, for modern automotive systems. |

| Book | Embedded Networking with CAN by Oliver Kasten (2008) | Discusses CAN bus implementation in embedded systems, focusing on hardware design and software drivers. |

| Journal Article | "Fault-Tolerant Communication in CAN-Based Systems" by T. Nolte et al. (2005) | Analyzes error handling mechanisms and fault tolerance strategies for critical CAN bus applications. |

These references provide a blend of theoretical foundations and practical insights, catering to engineers, researchers, and students working with CAN bus technology. For instance, Voss’s book offers a deep dive into CAN bus signaling and timing analysis, while Khayam’s survey contextualizes CAN bus within broader communication protocols. The ISO 11898 standard serves as a权威 reference for compliance and design guidelines, ensuring adherence to industry norms.

In recent years, research has focused on enhancing CAN bus security and performance. With the rise of connected and autonomous vehicles, protecting CAN bus from cyberattacks has become critical. Studies like "Security Analysis of the Controller Area Network (CAN) Bus" by M. Wolf et al. (2025) evaluate vulnerabilities such as message injection and propose intrusion detection systems. Additionally, advancements in Time-Triggered CAN (TTCAN) and CAN with Flexible Data Rate (CAN FD) continue to address bandwidth and latency challenges in next-generation vehicles.

In conclusion, CAN bus remains a cornerstone of real-time communication systems, supported by a wealth of English literature that spans its history, technical specifications, and emerging trends. The references listed above, along with ongoing research, underscore its enduring relevance and adaptability in evolving technological landscapes.

FAQs

-

What is the difference between classical CAN and CAN FD?

Classical CAN supports data rates up to 1 Mbps and a maximum data payload of 8 bytes per frame, making it suitable for low-bandwidth applications. CAN FD (Flexible Data Rate) enhances this by allowing data rates up to 8 Mbps and larger payloads (up to 64 bytes), improving efficiency for high-data-demand systems like ADAS. CAN FD also retains backward compatibility with classical CAN networks, ensuring seamless integration. -

How does CAN bus ensure fault tolerance in automotive systems?

CAN bus employs multiple fault-tolerance mechanisms, including error detection via CRC checks, bit monitoring, and error signaling. If a node detects an error, it transmits an error frame, prompting all nodes to discard the corrupted message and retry. Additionally, the differential signaling minimizes noise interference, while the multi-master architecture allows redundant nodes to maintain communication if one fails, ensuring system reliability.